Machine embroidery is a unique process whereby a particular sewing machine or embroidery unit machine that is used to develop distinctive patterns on fabrics. Besides that these types of special machines and it ideal for activities such as product branding, uniform advertisement, and corporate advertising.

Moreover, these machines are also used for machine embroidery for crafting projects and machine sewing as well.

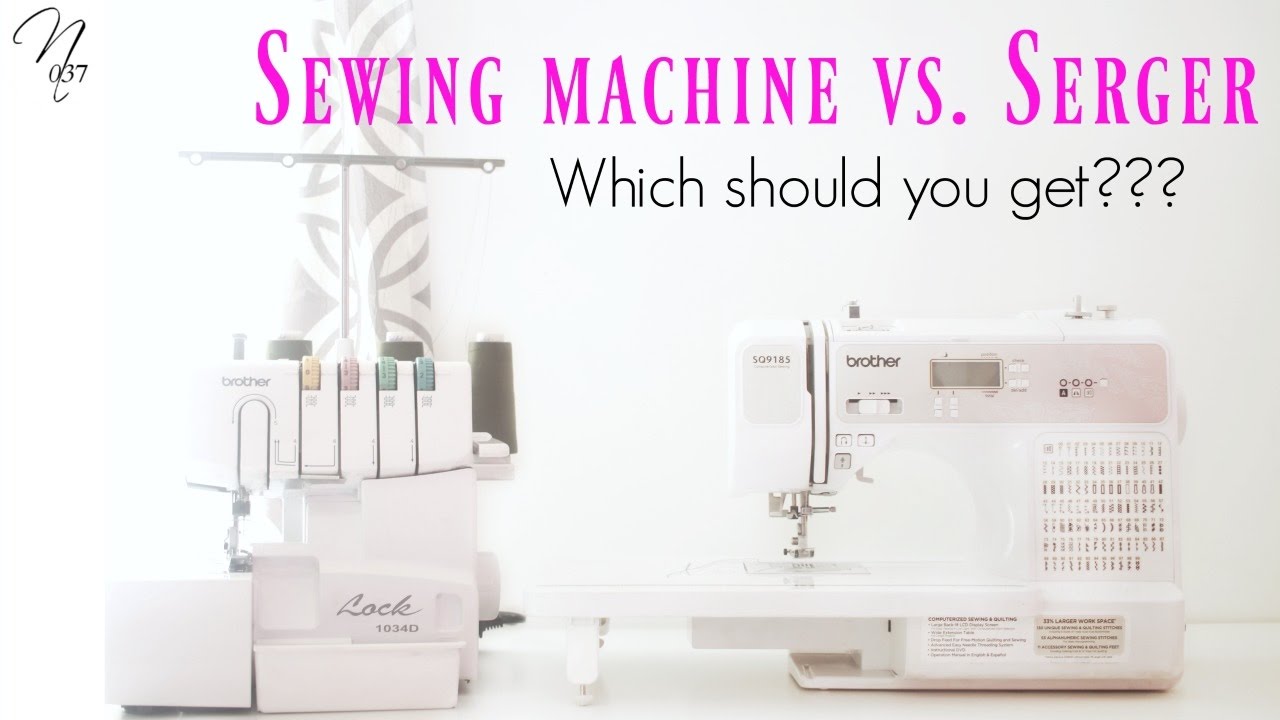

It’s important to note that there are multiple machines that are used for embroidery. Some of them include the free motion sewing machine, which comes with s special zig zag sewing unit. Additionally, much commercial embroidery ad is still performed with ink stitch embroidery; the patterns may be automatically and manually adjusted. The contemporary machine embroidery units are fitted with a special embroidery machine or sewing unit that is controlled by a special computer that has stored patterns that may have several threads or heads.

The consumer market is packed with a broad spectrum of embroidery units that come with as many different features:

Free motion machine embroidery

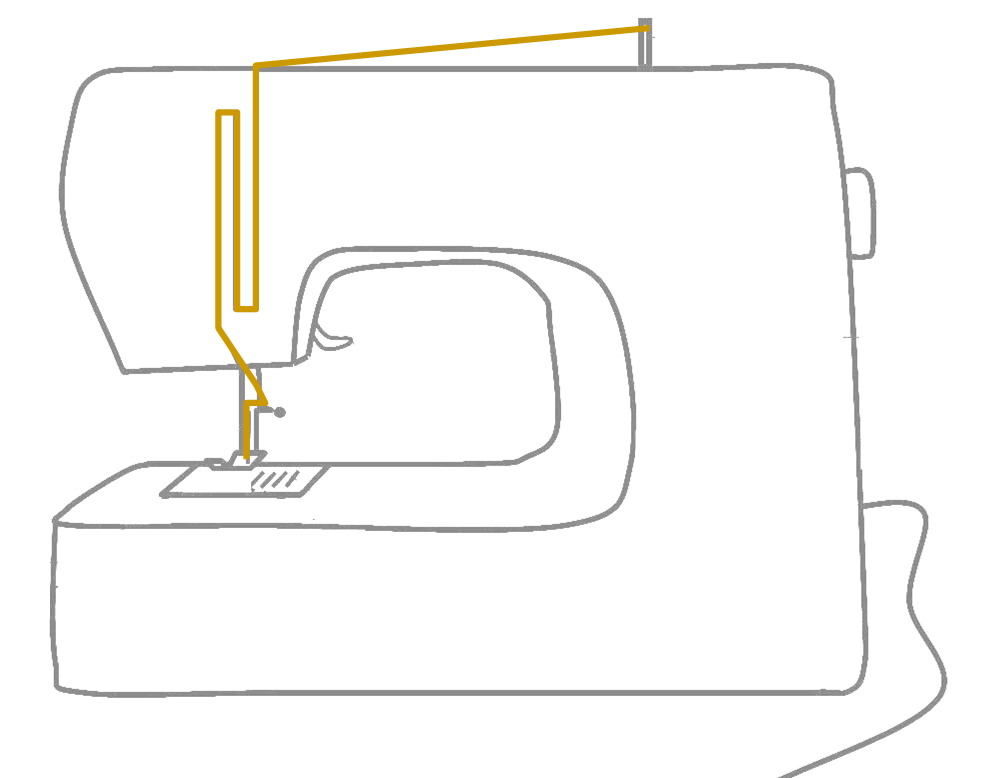

When it comes to this type of embroidery, the exclusive fabric embroidery designs are developed by using a device that is capable of producing zig zag patterns. Since these units are also used for tailoring, these type of machine often lack the automated features of a specialized embroidery machine. Creating the free motion machine embroidery the user has to run the machine by using special moves that are tightly integrated into the fabric and the needle to develop a new pattern. Besides that, the user is often inclined to reduce or perhaps cover the machine teeth and alternate the fabric with the use of hands.

Computerized machine embroidery

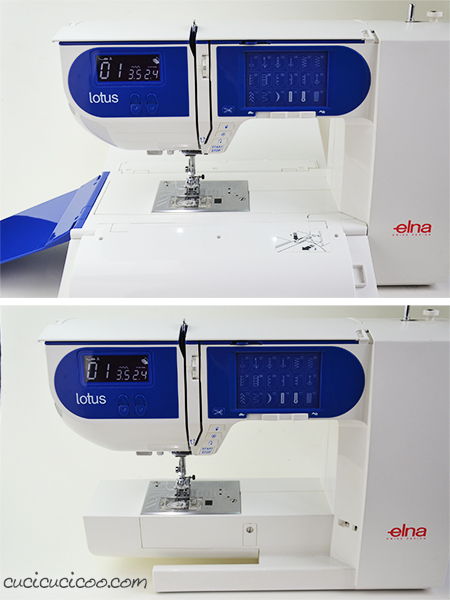

A significant portion of the contemporary embroidery machines come with computer manipulated that are mainly designed for embroidery. In most cases, these units are used in commercial and industrial locations for sewing systems to hold the framed edges of the fabric. Depending on its functionalities, this unit will come with a broad spectrum of different degrees to allow the user to input novel embroidery patterns. It’s important that these machines often come with a single needle and it necessitates that the use detached the thread color during the embroidery procedure.

While machine embroidery might seem like a relative procedure, it sometimes requires the competent and experience of a trained sewing professional. Some of the major steps in this type of sewing include

- Procure or develop your idea embroidery design in digital format that is compatible with your sewing machine

- Edit the design of the pattern and combine it with any additional patterns that you may require

- Load the final pattern into the embroidery unit and ensure that it’s in the correct format to suit your machine and your fabric as well

- Position the fabric on stable platform and then integrate it into the machine

- Start and observe the machine, all while changing the thread colors and troubleshooting the complications of the unit

Digitized embroidery is often purchased or created with special software. The file formats may fall into two general categories including the source formats and the machine formats as well. Once the embroidery pattern has been digitized, the user can use the special software to edit and combine the patterns with other special designs, A significant portion of embroidery programs allows the user to scale, move and rotate the unit to ensure that it suits your unique needs. Some of the contemporary software may allow the user to edit and eliminate the unwanted stitches specifically.

One important factor to consider when mitigating the effects of wrinkles and other notable complications is to ensure that you place the fabric on a flat platform. For example, items such as the large-sized embroidery patterns and the knits may require additional stabilization. The final step may often involve starting the embroidery machine and monitor its functionality. For the commercial embroidery machine, the procedure is often much more automated that for the conventional machines. A significant portion of the designs may require the use of more than one color and may also entail the use of additional processing to ensure optimal embroidery results. Since the conventional machine come with only a single needle, the user may have to change the needle and remove the thread manually.